Rolling mills

allpccloud GmbH offers powerful software for state-of-the-art simulation of flat rolling processes both offline and in Level 2 – automations. We use specialized high-performance FEM methods to deliver accurate results both for the roll gap and for the roll stack.

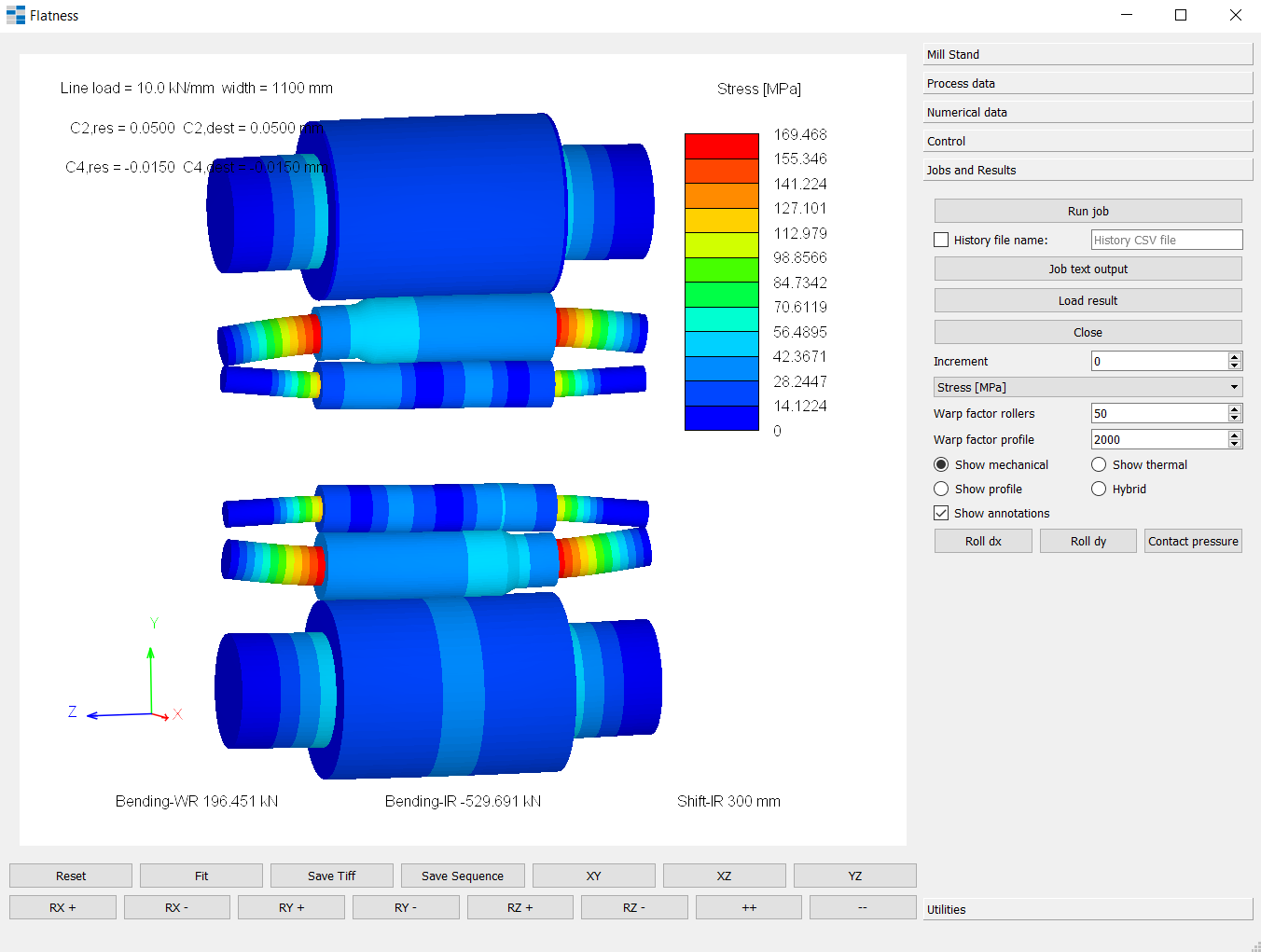

Flatness software

Accurate knowledge of the roll gap form is essential for competitive flat rolling mill operation. Make use of our flatness software to analyse your roll stack, optimize the roll gap profile and get accurate settings for the flatness actuators.

The computing kernel can be embedded into other applications and be used in automation systems.

Pass schedule software

Overall simulation of flat rolling mill lines. Compute roll gaps and complete pass schedules in single- or multi-stand rolling lines, single-pass or reversing, steady-state or transient.

Suitable for usage in automation systems. Simulation of the complex mechanical system of the elastic-plastic strip and the elastic work rolls is done with GPU acceleration, yielding fast and accurate results for optimized mill operation.